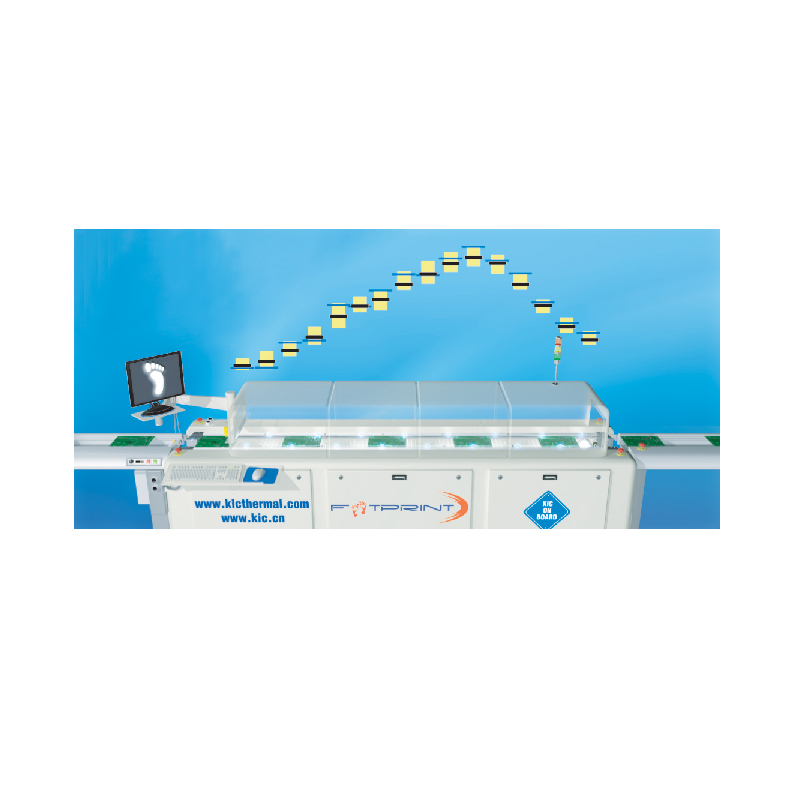

FootPrint

1-Click Oven Monitoring

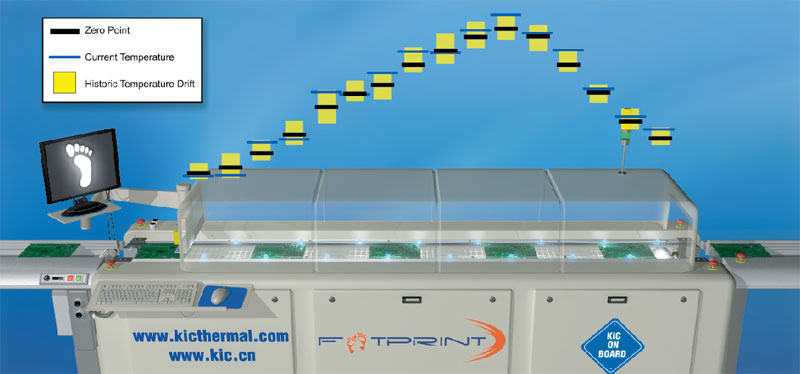

The KIC Footprint Concept

● The alternative to frequent profiling and thermal process windows is to monitor the machine drift

● The Footprint system monitors the oven temperature variations along the conveyor

● Conveyor speed is also measured in real-time

● The key decision is to determine allowable versus excessive drift

● The KIC Footprint can make that decision for you by automatically measuring the acceptable drift, and only alert the user when the conditions reach danger level

● Users cans also select the basic monitoring mode with no alarms. The Footprint will simply record and display the changing conditions in the oven

KIC Footprint hardware

● 30 thermocouple sensors are permanently installed in reflow oven thnnel. They are housed in tow probes, each containing15 sensors

● The sensors are attached with brackets to the left and right edge conveyors in close proximity to PCBs as they are processed in the oven

● The probes are connecte to a data acquistion unit that delivers the information to the computer. The Footprint system can use the oven computer or a separate PC

● One speed encoder is attached to the conveyor gear to continuously measure the speed

Selectable programming modes for oven monitoring and drift limits

1. 1-Click Programming

a. 1-Click to start oven monitoring without alarms

b. 1-Click to start oven monitoring with default alarm setup. In this mode the software looks at the oven drift in the recent period of time and sets the alarm accordingly

2. Load the settings of a previous monitoring run

3. Advanced programming

The user can select upper and lower limits to drift for individual TC sensors and conveyor speed

Monitoring Function

1. Real-time oven temperature and conveyor speed variations are displayed on the screen. This 'video' can be stored for record keeping and it can be retrieved at any time

2. The oven drift is displaced grapically for each temperature sensor and for the speed sensor with the following legend:

a. Red line denotes the temperature zero point.This is the actual temperature that the sensor measured when the monitoring program was started

b. Gray line with green dot shows the current temperature

c. Gray shaded area. This area depicts how the temperature had drifted above and below the zero point since monitoring started. No temperature was measured above or below the gray shaded area

System Components

30 ea. Thermocouple sensors embedded in the reflow oven

1 ea. Speed encoder

1 ea. E-TPU data acquisition box with cabling

1 ea. Alarm relay

1 ea. Light Tower

1 KIC Footprint software

Compatibility

● The Footprint system can be ordered for a new reflow oven or it can be retrofitted to a previously installed oven.

● The Footprint system is compatible with virtually all reflow ovens in the market . Please contact KIC for confirmation of compatibility to your ovens.

Minimum System Requirements

Dual Core / 1 GHz Processor PC with 2 GB RAM

2 GB available storage

Video 1024 x 768 resolution / 16-bit

1 available USB port (for data download)

1 available USB port (for software key)

1 available Ethernet port or 1 available USB port with Ethernet to USB

Microsoft® Windows® XP, Vista, or 7. (32-bit or 64-bit)